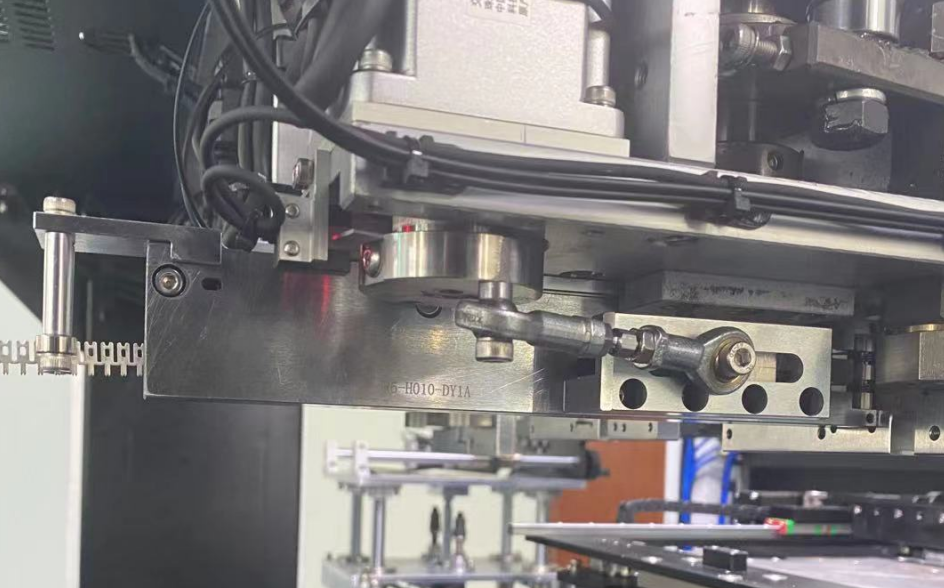

Ngationei kuti inoshanda sei:

What iriPress-fit?

Press-fit kupindirana pakati pezvikamu zviviri umo chimwe chikamu chinomanikidzwa pasi pekumanikidzwa kupinda mugomba diki mune imwe.

Chaizvoizvo, imhando yekupindira inokodzera.

Press fit tekinoroji inoshandiswa zvakanyanya, uye kubatana paPCB ndechimwe chezvayakajairwa kuita.

Kana tichitsanangura muchiChinese, tinowanzo shandisa mazwi akasiyana senge crimping, press fitting, uye crimping.Iyo indasitiri inowanzo shandiswa kushandisa zvakananga "Press fit" kutsanangura.Iyo inonyanya kutariswa yechinyorwa ichi zvakare iyo yekutsikisa inokodzera application muPCB indasitiri (anoverengeka akajairika mapini anopindirana).

Ndezvipi zvakanakira Press fit?

Nzira huru dzekuisa zvikamu paPCB ndeye welding uye kudzvanya fit.Ngatimboenzanisai zvakanakira uye zvakaipira nzira mbiri idzi dzekubatanidza nedzimwe dzakajairwa data.

| Soldering | Press-fit | |

| kushandiswa | 30-40 kW | 4-6 kW |

| zvakatipoteredza | Welding mweya uye pekugara | Hapana pekugara |

| mutengo | Inoda PA, PPS | Hapana dambudziko rekuchengetedza tembiricha, shandisa yakaderera mutengo zvinhu zvakaita sePBT, PET nezvimwe. |

| Equipment | Kudyara kukuru uye mutengo mukuru wenzvimbo | Yakaderera invest uye diki saizi nzvimbo |

| Nzvimbo iripo | 5-15mm | 2mm |

| Defect rate | 0.05 zvakakodzera | 0.005 fit |

Kubva pane data rekuenzanisa, isu tinogona kuona kuti Press fit iri nani PCB yekubatanidza nzira pane welding maererano nezvimwe zviratidzo zvekuita.Ehe, welding haina maturo, kana zvikasadaro hapazovi neakawanda welding mapoinzi paPCB.Semuenzaniso, welding kazhinji ine kushivirira kwakakura kweiyo dimensional kushivirira kwepini, uye iyo welding yekubatanidza yakagadzikana, Zvisinei, Press Fit iri nani mune akawanda maficha zviratidzo.

Common Press inokodzera dhizaini nzira

Usati waunza nzira yekugadzira, zvinodikanwa kuunza mazwi maviri anowanzo shandiswa:

PTH: Yakaputirwa kuburikidza neHole

EON: Ziso retsono

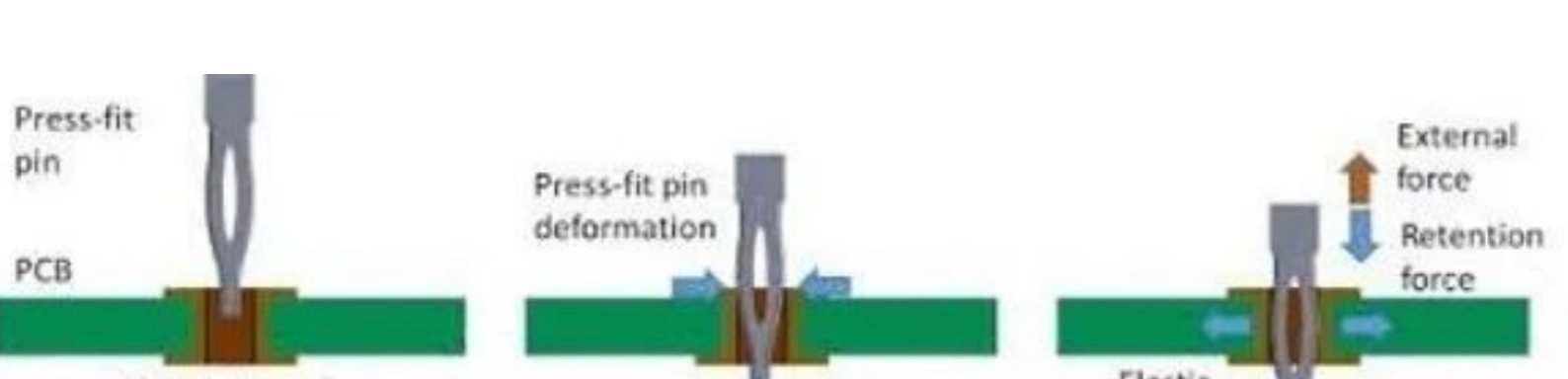

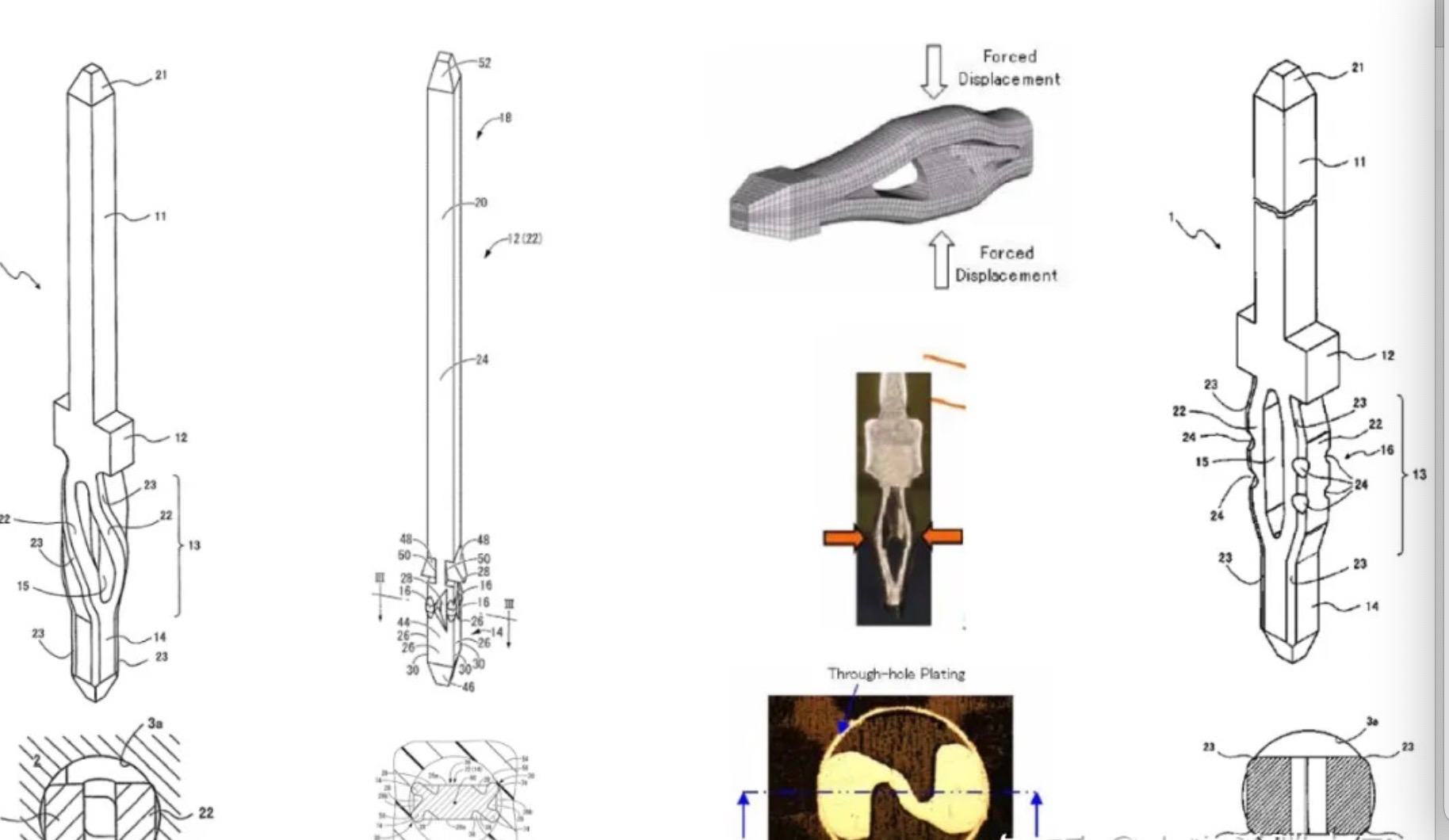

Parizvino, mapini anoshandiswa paPress fit pini ane elastic pini, anozivikanwawo semapini anoenderana, ayo anowanzo kukura muhupamhi kupfuura PTH.Munguva yegungano, nhengo dzetsono dzichave dzakaremara, zvichikonzera kubatana kwepamusoro neiyo yakasimba PTH.Kuenzaniswa netsono yakasimba, iyo inopindirana tsono inogona kubvumira yakakura PTH kushivirira.

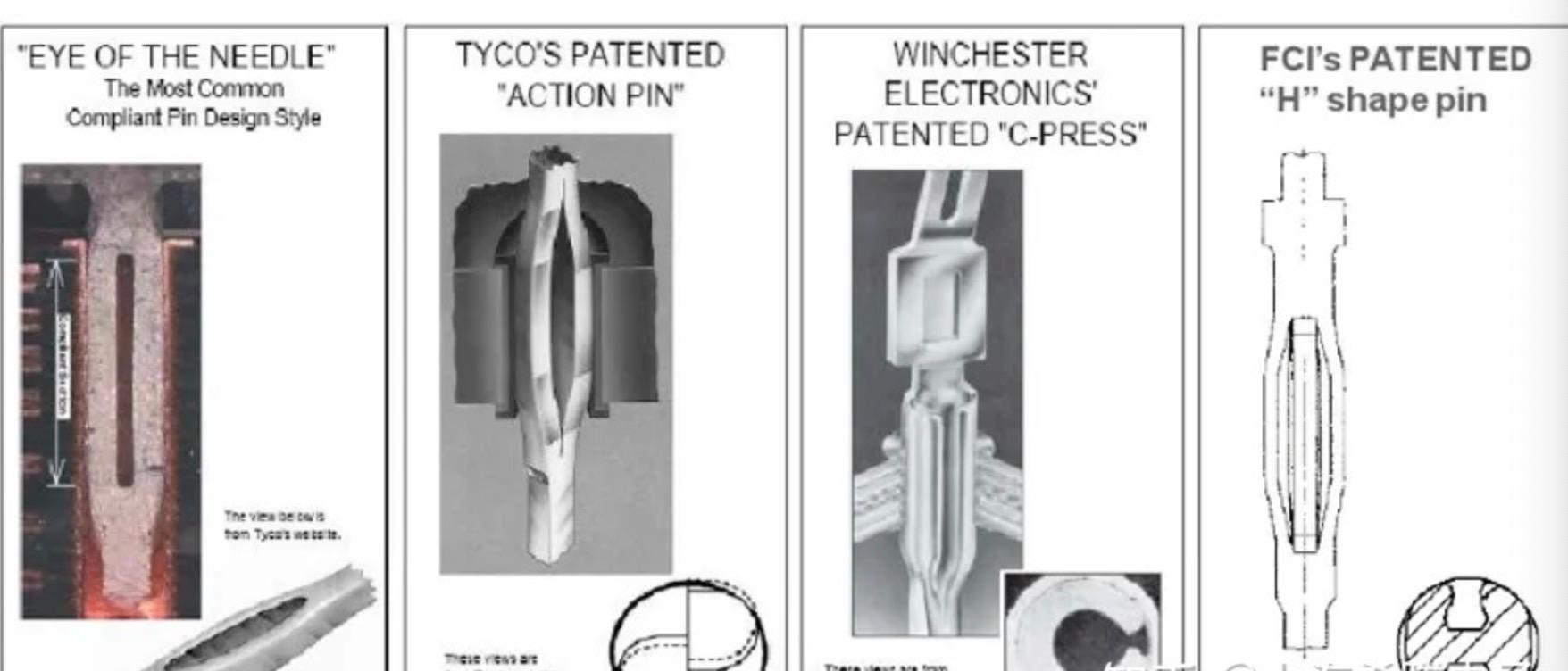

Iyo pini buri tsono zvishoma nezvishoma yave iyo huru mumusika.Iyo iri nyore mukugadzira uye inogona kushandiswa neyakavhurika patents.Kunyangwe iyo isingade yakawandisa dhizaini dhizaini, inogona zvakare kushandiswa neyakagadzirirwa-yakagadzirwa dhizaini mhinduro, iyo ine hunhu hwekuderera kuisa simba uye yakakwirira yekuchengetedza simba.

Mufananidzo uri pamusoro unoratidza akati wandei akajairwa pini/terminal zvimiro.Yokutanga ndiyo yakajairika dhizaini chirongwa.Iyo yakakosha pinhole dhizaini dhizaini iri nyore muchimiro, asi inoda yakakwirira symmetry nenzvimbo;Yechipiri ndiyo patent chigadzirwa cheTE Kambani.Kubva pane iyo pinhole chimiro, ine zvishoma zvishoma kutenderera angle, iyo inogona kuenderana nemakomba akasiyana.Zvisinei, ine zvinodiwa zvakakwirira zvegomba dhayamita, uye inobudisa imwe simba rekutenderera pagomba;Yechitatu ndeye Winchester Electronics 'yapfuura patent "C-PRESS", iyo inoratidzirwa neC-chimiro kubva pamuchinjikwa chikamu.Zvakanakira ndezvekuti simba rekudzvanya rinoenderera mberi, iyo PTH deformation idiki, uye chakashata ndechekuti PTH ine diki aperture yakaoma kuwana;Yekupedzisira ndeye H-mhando yekubata pini yeFCI Company.Zvakanakira ndezvekuti zviri nyore kudzora kana crimping, asi chakashata ndechekuti zvakaoma kugadzira pini yekubata.

Zvinhu zvakajairika uye maitiro ekugadzira

Zvishandiso zvakajairika zvePin zvinosanganisira tin bronze (CuSn4, CuSn6), ndarira (CuZn), uye chena mhangura (CuNiSi), pakati peiyo chena mhangura ine yakakwirira conductivity, uye tembiricha yekushandisa inogona kudarika 150 ℃;Iyo yekupfeka inowanzoputirwa ne electroplating kana inopisa dip plating μ m + 1 μ M yeNi + Sn, SnAg kana SnPb, nezvimwewo Sezvatsanangurwa pamusoro apa, chimiro chePini chakasiyana, uye chinangwa chikuru ndechekugadzira Pini ine diki. kudzvanya simba uye hombe kubata simba pasi pemamiriro ekugadzira nyore uye mutengo wakaderera.

Chinhu chinowanzo shandiswa chePTH igirazi faibha+epoxy resin+copper foil, ine ukobvu> 1.6, uye iyo yekupotera inowanzoita tin kana OSP.Chimiro chePTH chiri nyore.Kazhinji kutaura, nhamba yePCB layers yakakura kupfuura 4. Iyo aperture yePTH inowanzoomesesa, uye izvo zvinodiwa zvinoenderana nekugadzirwa kwePini.Kazhinji, ukobvu hwemhangura plating inenge 30-55 μ m.Ukobvu hwekuisa tin hunowanzo> 1 μ m.

Ongororo yepress fit / dhonza kunze maitiro

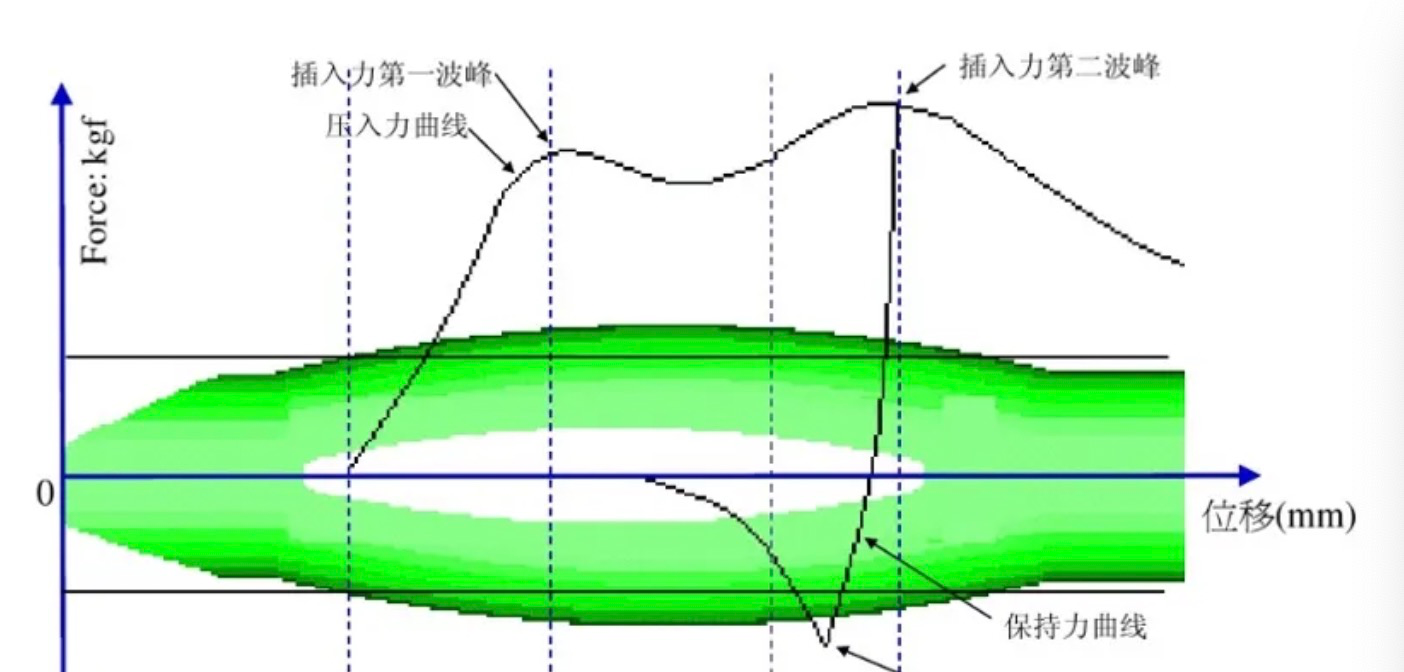

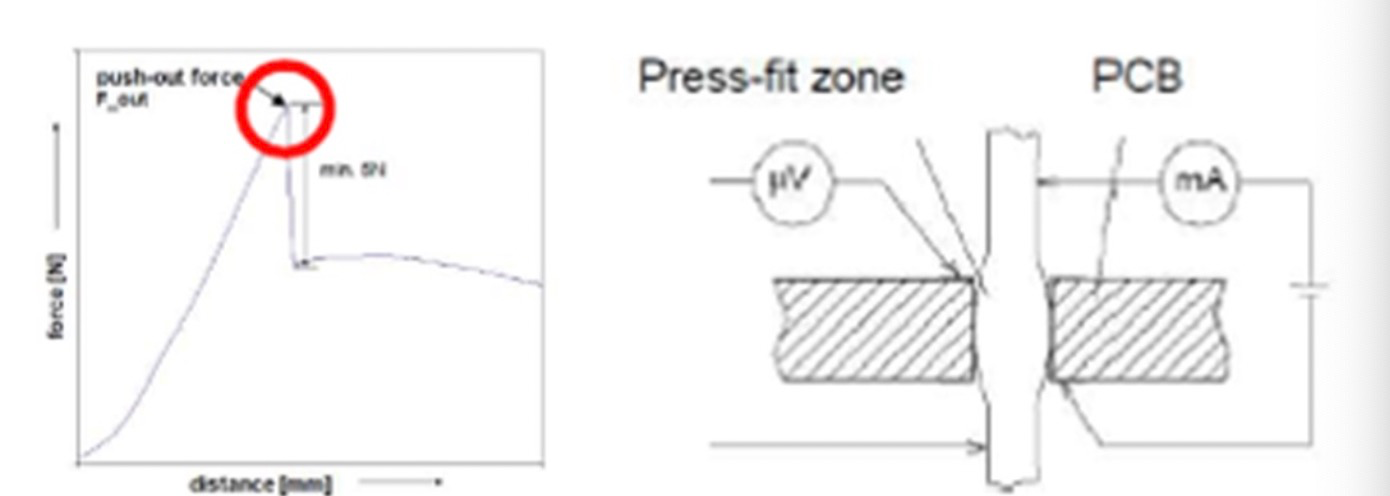

Tichitora iyo yakajairika pinhole chimiro semuenzaniso, sekuratidzwa pamufananidzo uri pazasi, pane yakajairwa kudzvanywa curve shanduko mune yese maitiro ekudzvanya mukati nekudhonza kunze, ayo ane hukamawo nekugadzirwa kwePin.

Press in process:

1. Pini inoiswa mugomba, uye muromo unopinda usina deformation

2. Pini inotanga kudzvanya mukati, EON inotanga kukanganisa, uye yekutanga wave peak inooneka mukutsikirira.

3. Pini inoramba ichidzvanya, EON haina kana imwe deformation, uye simba rekudzvanya rinodzikira zvishoma

4. Pini inoramba ichitsikirira pasi, ichikonzera kumwe deformation, uye yechipiri wave peak

Inoonekwa mukutsikirira

Mukati me100 seconds mushure mekupedzwa kwekudhinda, simba rekuchengetedza rinodonha nokukurumidza, nekudonha kwe20%.Pachava nemisiyano inoenderana zvinoenderana neakasiyana mapini magadzirirwo;Maawa makumi maviri nemana mushure mekumisikidzwa kwemuchina, iyo inotonhora yekubatira yePin nePTH inopedzwa.

Izvi zvinokonzerwa nemaitiro emuviri wesimbi, uye pane nzvimbo shoma yekuvandudza.Inogona kuongororwa kana iyo yekupedzisira yekuchengetedza simba inosangana nezvinodiwa dhizaini yechigadzirwa kuburikidza ne push out force test.

2. Vamwe kukundikana modes panguva Pin kuisa

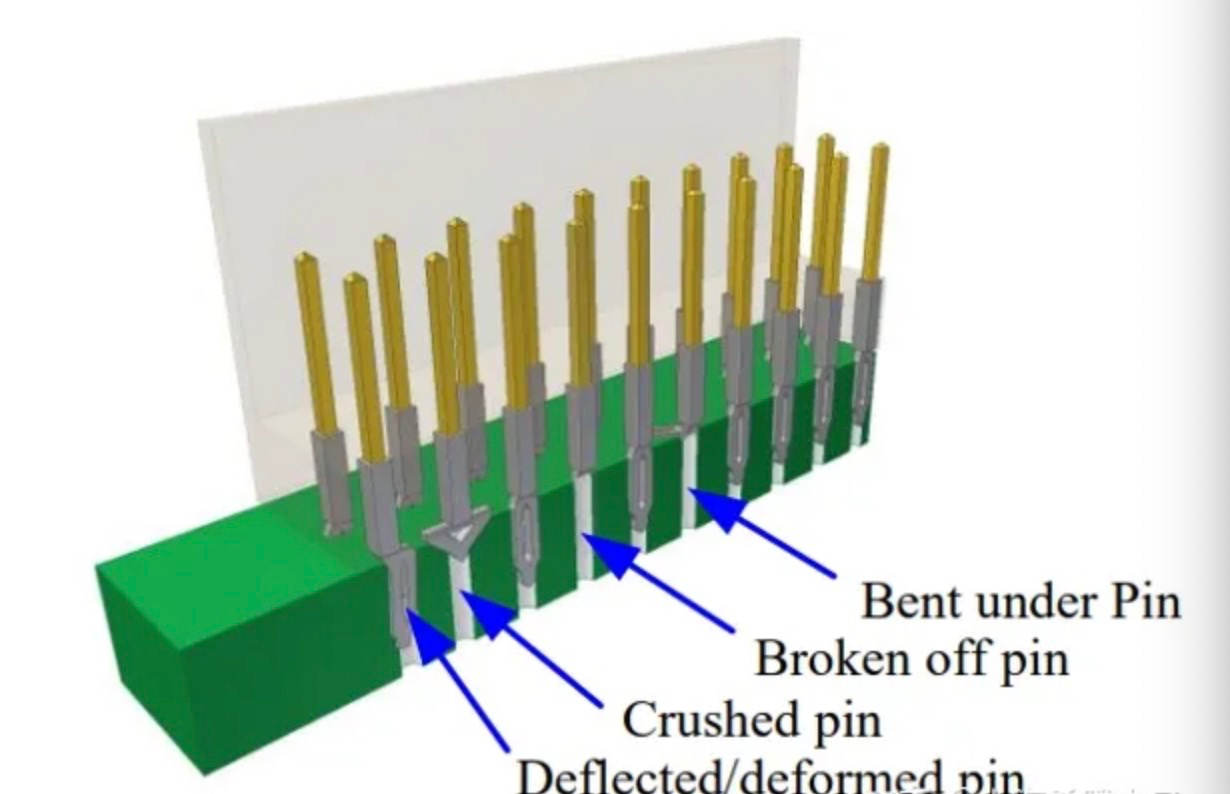

Sezvinoratidzwa mumufananidzo uri pasi apa, pini inogona kukanganisa, kupwanyika, kupwanyika, kuputsika uye kukotama panguva yekuiswa.

Aya ndiwo anogona kutadza modhi yepini yekubata panguva yekukodzera kudhinda maitiro.Sezvo pini yekubata ichida kuiswa muPTH, zvinokwanisika kuti haigone kuonekwa nemeso mushure mekudzvanya, uye kukuvadzwa kwesimba remagetsi kunogona kusaonekwa kuburikidza nemagetsi ekuita bvunzo.

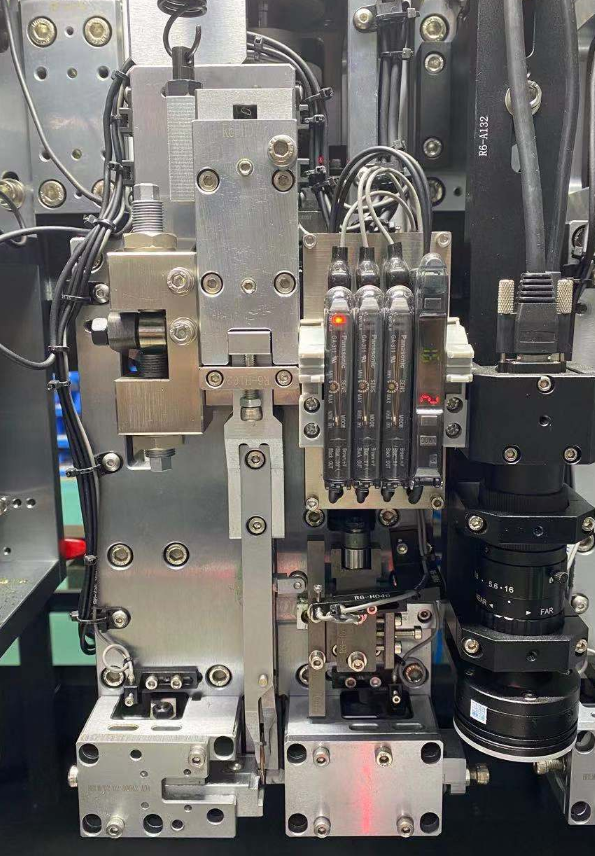

Aya maitiro ekutadza anofanirwa kutariswa panguva yekumisikidzwa kwenhau.PROMESS inopa curve corridor, hwindo, yakakwira uye yakaderera kukosha uye dzimwe nzira dzekutarisa kuti ive nechokwadi chekuti iyo yese yekutsikirira yepini yega yega inodzoreka uye yakavimbika.Iwe unogona kuona iyo kesi inoratidzwa muvhidhiyo zvakare.PROMESS inopa yakakwirira-chaiyo, 100% maitiro ekugadzirisa mhinduro kuve nechokwadi chekuti zvigadzirwa zvese zvinobuda mufekitori hazvina zvigadzirwa zvakakanganisika, Iyo nzira yekudzora inogona zvakare kuderedza marara emaindasitiri ePCB board kusvika pamwero wakati uye kuderedza mutengo wekugadzira.

3. Short Circuit

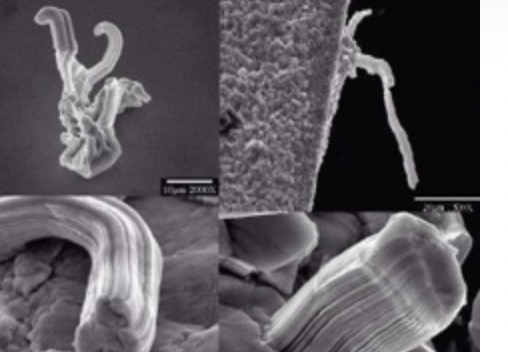

Pamusoro petini yakachena, kushushikana kunosimudzira kukura kweti Whisker, iyo inotungamira kupfupi yedunhu redunhu pabhodhi rakadhindwa redunhu, nokudaro kuisa mungozi basa remodule.Madhizaini ekudzikisa kukura kwemarata anosanganisira kudzikisa simba rekupinza uye kuderedza ukobvu hwemarata.

Zvakajairwa PTH zvekupfekedza zvinhu zvinosanganisira mhangura, sirivheri, tini, nezvimwe

Nzira yekugadzirisa sei dambudziko rematani ndebvu?

Panguva yekudzvanya, simba rekudzvanya harizove rakakura, iro rinova kutonga kwekudzvanya maitiro.Mushure mekudzvanya, kuongororwa kwesampling kunogona kuitwa, uye ndebvu dzemarata dzinofanirwa kucherechedzwa kwemavhiki gumi nemaviri.

4. Vhura dunhu

Jet effect/ dhonza pasi:

Munguva yekutsikirira muPini, iyo yakadhindwa yedunhu bhodhi inogona kunge yakakuvadzwa nemichina.Kana kukwenya kwakanyanyisa, pamusoro pebhodhi redunhu richacherwa, kukwenya kunowedzera, uye pakupedzisira PTH ichasundirwa kunze nechikamu.Kuderedza kudzvinyirira kunogonawo kudzivirira jet effect.

Whitening effect/delaminate:

Panguva yekumisikidzwa kwedhinda, yega yega dhizaini yedhidhi redunhu bhodhi inosvinwa.Kana simba rinoshandiswa rakanyanya kukura kana PTH isina kugadzikana, iyo yakadhindwa yedunhu bhodhi inogona kuderedzwa.Mushure menguva, hunyoro huchapinda mumitsero yebhodhi redunhu rakadhindwa, zvichikonzera kuderedzwa kwekuzviparadzanisa nevamwe

Aya matambudziko maviri anogona kudzorwa kune imwe nhanho panguva yekumisikidzwa kwenhau nekudzora simba rekudzvanya.Mushure mekugadzirisa kudhinda kwapera, chigadzirwa chinogona zvakare kuongororwa nenzira yekubata kuramba bvunzo uye metallographic ongororo.Iyo yekusangana yekupikisa bvunzo inogona kushandiswa seyenguva yekuyedza chinhu, uye iyo metallographic ongororo pachayo inoparadza kune chigadzirwa, saka yenguva dzose sampling yekuongorora inogona kuitwa.

Nzira dzekuongorora kuvimbika kwechigadzirwa

Imwe yedzakajairika nzira dzekuona ndeyekuchembera bvunzo uye imwe yacho yekubatanidza maitiro ebvunzo

Kuchembera kutevedzera nyika mushure menguva yakareba yekushandiswa kuburikidza nemidziyo yekuyedza.Nzira dzakajairika dzekukwegura dzinosanganisira:

1. Kudziya kwemvura: - 40 ℃ ~ 60 ℃, kuenderera kushanduka kwemaminetsi makumi matatu

2. Kupisa kwepamusoro: 125 ℃, 250 maawa

3. Kutevedzana kwemamiriro ekunze: Kupisa kwemaawa gumi nematanhatu → maawa makumi maviri nemana kuchipisa uye kune mwando → maawa maviri tembiricha yakaderera →

4. Vibration

5. Kuora kwegesi: mazuva gumi, H2S, SO2

Muedzo wacho unonyanya kuyedza simba rekusundidzira uye kushanda kwemagetsi.

Nzira dzakajairika dzinosanganisira:

1. Pushira kunze simba (simba rekubata): > 20N (maererano nekugadzirwa kwechigadzirwa zvinodiwa)

2. Bata kuramba: < 0.5 Ω (maererano nekugadzirwa kwechigadzirwa zvinodiwa)

Nguva yekutumira: Nov-10-2022

Youtube

Youtube