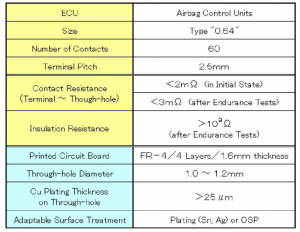

A. Tsanangudzo pfupiso

Madiro eiyo press-fit connector yatakagadzira ndeye

zvakapfupikiswa muTable II.

MuTafura II, "Size" zvinoreva hupamhi hwekusangana kwechirume (iyo inonzi "Tab Size") mumm.

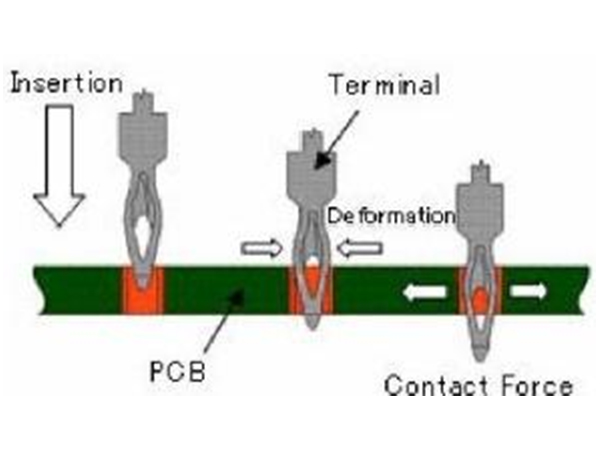

B. Yakakodzera Kubatana Simba Range Kutsunga

Senhanho yekutanga yepress-fit terminal dhizaini, isu tinofanira

sarudza huwandu hwakakodzera hwekubatana nesimba.

Nechinangwa ichi, iyo deformation hunhu madhayagiramu e

materminal uye nemaburi-maburi anodhirowa zvine hurongwa, sezvakaratidzwa

muFig. 2. Zvinoratidzwa kuti masimba ekusangana ari muakisi yakatwasuka,

nepo terminal saizi uye kuburikidza-gomba madhayamita ari mu

horizontal axis zvichiteerana.

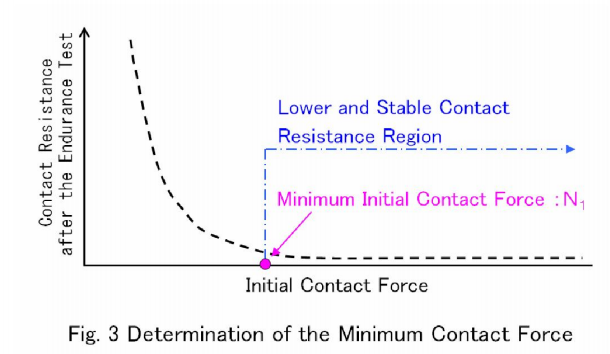

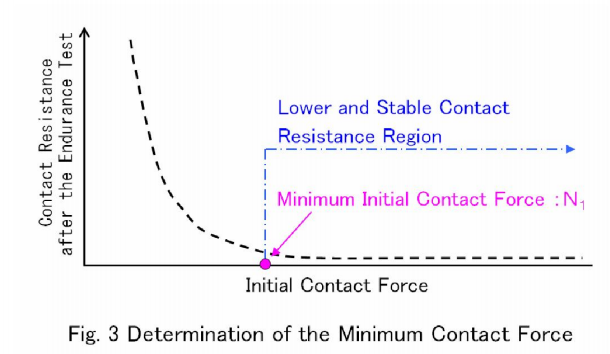

C. Minimum Contact Force Kutsunga

Iyo shoma yekubata simba yakatemwa ne (1)

kuronga kusangana kwekupikisa kunowanikwa mushure mekutsungirira

bvunzo muakisi yakatwasuka uye yekutanga kubata simba mukati yakachinjika

axis, sezvinoratidzwa muFig. 3 schematically, uye (2) kutsvaga

shoma yekubata simba sekuvimbisa kubata kuramba kuve

yakaderera uye yakagadzikana.

Zvakaoma kuyera simba rekubata zvakananga kune iyo press fit yekubatanidza mukuita, saka takaiwana seinotevera:

(1) Kupinza materminal mumaburi, ane

madhayamita akasiyana-siyana kupfuura chiyero chakatarwa.

(2) Kuyera hupamhi hwekupedzisira mushure mekuiswa kubva ku

cross section cut samples (somuenzaniso, ona Fig. 10).

(3) Kushandura hupamhi hwekupedzisira hwakayerwa mu (2) kuita

kubata simba uchishandisa deformation hunhu

dhayagiramu yeiyo terminal yakawanikwa chaizvo sezvakaratidzwa mukati

Mufananidzo 2.

Mitsetse miviri yeterminal deformation inoreva imwe ye

hukuru uye hudiki terminal saizi nekuda kwekupararira mukati

nzira yekugadzira zvichiteerana.

Tafura II Scecification yeConnector yatakagadzira

Zviri pachena kuti simba rekubatana rakagadzirwa pakati

materminals uye kunyange-maburi anopiwa nemharadzano yemaviri

mifananidzo yezviteshi uye kuburikidza-maburi muFig. 2, iyo

zvinoreva mamiriro akaenzana ekutsikirirwa kwemagumo uye kuburikidza nekuwedzera kwegomba.

Isu takasarudza (1) iyo shoma yekubata simba

inodiwa kuita kusangana kwekupokana pakati pematerminals uye

kunyange-maburi akadzika uye akanyanya kugadzikana pamberi / mushure mekutsungirira

bvunzo dzemusanganiswa wemadiki terminal saizi uye

kukwirira kuburikidza-gomba dhayamita, uye (2) simba guru

zvakakwana kuti ive nechokwadi chekudzivirira kwekudzivirira pakati pepedyo

kuburikidza-maburi inodarika kukosha kwakatarwa (109Q yeizvi

Development) zvichitevera bvunzo dzekutsungirira dze

kusanganiswa kwehukuru hwekupedzisira hukuru uye hushoma

kuburikidza-gomba dhayamita, uko kuderera kwekudzivirira

Kupokana kunokonzerwa nekutorwa kwemwando mu

yakakuvadzwa (delaminated) nzvimbo muPCB.

Muzvikamu zvinotevera, nzira dzinoshandiswa kusarudza

hushoma nehukuru hwekusangana masimba zvichiteerana.

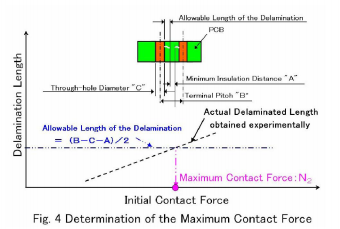

D. Maximum Contact Force Kutsunga

Zvinogoneka kuti interlaminar delaminations muPCB inokurudzira

kuderedzwa kwekudzivirira kwekudzivirira pakupisa kwakanyanya uye mukati

mhepo ine hunyoro kana iri pasi pekunyanya kusangana nesimba,

iyo inogadzirwa nekubatanidzwa kwepamusoro

saizi yekugumira uye iyo shoma kuburikidza ne-gomba dhayamita.

Mukusimudzira uku, iyo yakanyanya kubvumidzwa yekubata simba

yakawanikwa sezvinotevera;(1) kukosha kwekuedza kwe

shoma inobvumirwa insulation kureba "A" muPCB yaive

yakawanikwa pachine kuedza, (2) inobvumirwa

kureba kwe delamination kwakaverengerwa geometrically se (BC A)/2, uko "B" na "C" ndiwo mbiru inogumira uye

kuburikidza-gomba dhayamita zvichiteerana, (3) iyo chaiyo delamination

kureba muna PCB siyana kuburikidza-gomba diameters kwave

akawanikwa achiyedza uye akarongwa pakureba kwakaderedzwa

vs. dhayagiramu yesimba rekutanga, sezvakaratidzwa mumufananidzo 4

schematically.

Pakupedzisira, iyo yakanyanya kubata simba yakatemwa zvakadaro

sekuti usapfuure hurefu hunobvumirwa hwe delamination.

Iyo yekufungidzira nzira yekubatana masimba yakafanana ne

zvakataurwa muchikamu chakapfuura.

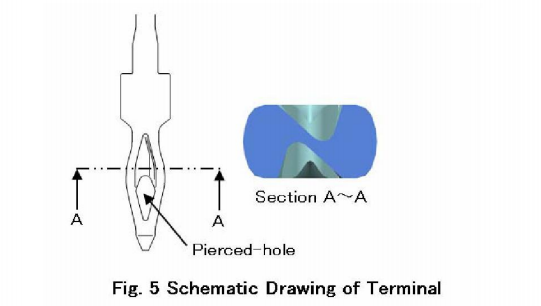

E. Terminal Shape Dhizaini

Iyo terminal shape yakagadzirwa kuti igadzire

simba rekubata rakakodzera (N1 kusvika N2) mune yakatemwa kuburikidza neburi

dhayamita renji uchishandisa mativi matatu ane magumo ekupedzisira

nzira (FEM), kusanganisira mhedzisiro yepre-plastiki deformation

kukurudzira mukugadzira.

Nekuda kweizvozvo, isu takatora terminal, yakaumbwa senge

"N-shape cross chikamu" pakati penzvimbo dzekusangana pedyo ne

pasi, iyo yakagadzira simba rinenge rakafanana rekusangana

mukati mezvakatemerwa kuburikidza-buri dhayamita renji, ine a

buri rakaboorwa pedyo nemuromo rinobvumira kukuvara kwePCB kuve

yakaderedzwa (Fig. 5).

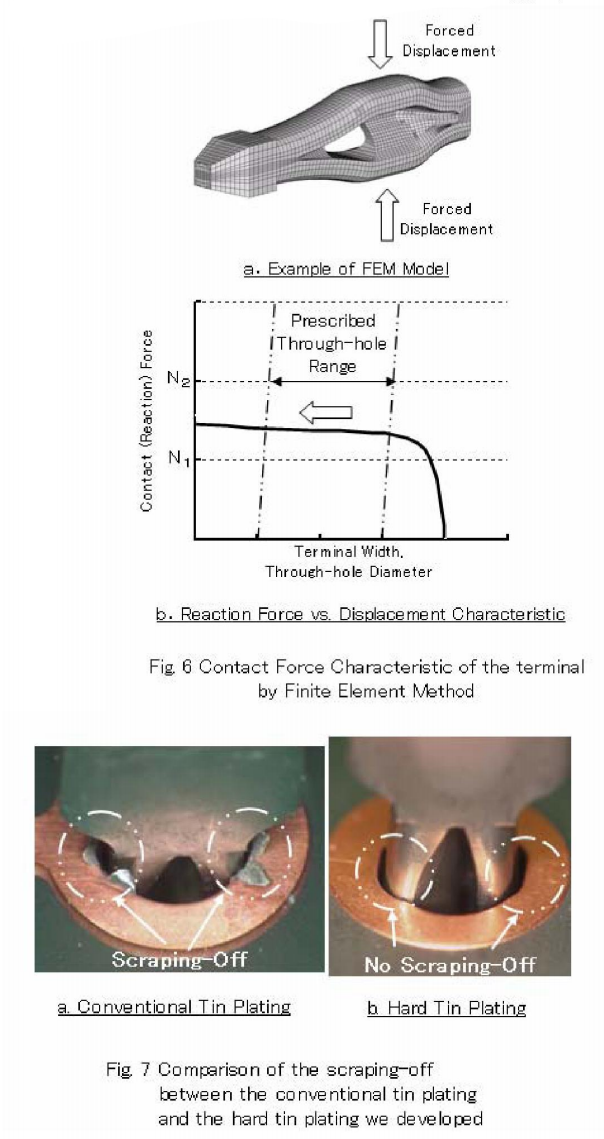

Kuratidzwa mumufananidzo 6 muenzaniso wevatatu-dimensional

FEM modhi uye simba rekuita (kureva, simba rekubata) vs

displacement diagram yakawanikwa analytically.

F. Kuvandudzwa kweHard Tin Plating

Kune nzira dzakasiyana dzekurapa dzekudzivirira

oxidization yeCu paPCB, sekutsanangurwa kwazvino muII - B.

Panyaya yesimbi plating pamusoro kurapwa, akadai

tin kana sirivheri, kuvimbika kwekubatanidza kwemagetsi kwepress-fit

tekinoroji inogona kuvimbiswa nekusanganiswa ne

zvakajairika Ni plating zviteshi.Nekudaro mune iyo OSP,tin plating pamaterminals inofanira kushandiswa kwenguva yakarebaterm yemagetsi kubatana kuvimbika.

Nekudaro, yakajairwa tin plating pamaterminal (ye

semuenzaniso, we1ltm ukobvu) inogadzira iyo yekukwenya-kurezve tinpanguva yekuisa terminal.(Mufananidzo. "a" mumufananidzo 7)

uye uku kukwesha-kure zvimwe kunokonzera mapfupi-sekete nematerminals ari pedyo.

Naizvozvo takagadzira rudzi rutsva rwerata rakaoma

plating, iyo isingatungamiriri kune chero tin kukweshwa uyeiyo inovimbisa kuvimbika kwekubatanidza magetsi kwenguva refupanguva imwe chete.

Iyi nyowani yekuisa maitiro ine (1) yakawedzera mutete tin

kuisa pasi pasi, (2) kupisa (tin-reflow) maitiro,

iyo inoumba iyo yakaoma metallic alloy layer pakati pe

underplating uye tin plating.

Nekuti iyo yekupedzisira yasara yerata plating, ndicho chikonzero

yekukwenya-kure, pamaterminal inova yakaonda zvakanyanya uye

inogovera zvisina kufanana pane alloy layer, hapana kukwesha-kureyetin yakasimbiswa panguva yekuisa (Mufananidzo "b" mukatiMufananidzo 7).

Nguva yekutumira: Zvita-08-2022

Youtube

Youtube